Retention time and mixing - Single Shaft Conditioner (For Food, Aqua Feed, and Pet Food)

IDAH pre-conditioner system is designed to incorporate heat, moisture, and time, which are the three major factors in cooking. The unique design of every pre-conditioner provides the most optimum cooking action to the material. Our advanced pre-conditioning technology pre-conditioner system consists of three major designs, differential diameter conditioner, long-term conditioner, and single shaft conditioner.

A Pre-conditioner system is applied for a wide range of feed and biofuel production. Optimized control for better retention time and mixing in animal feed, pet food, and aqua feed (floating and sinking). The main function is for cooking and hydration of the material.

In aqua feed, the “High Moisture Pelleting” method can be achieved through our advanced pre-conditioning technology to ensures sufficient cooking by carefully control the incorporation of heat, moisture and time, for the production of high-quality feeds with good water stability to the market.

In animal and poultry feed, our advanced pre-conditioning technology is not only used for altering product quality but more importantly, is used to lower bacterial contamination numbers.

In biofuel production, either from RDF or wood, pre-conditioning will help to soften the fibrous material by incorporating moisture and heat, which will help in the pelleting process.

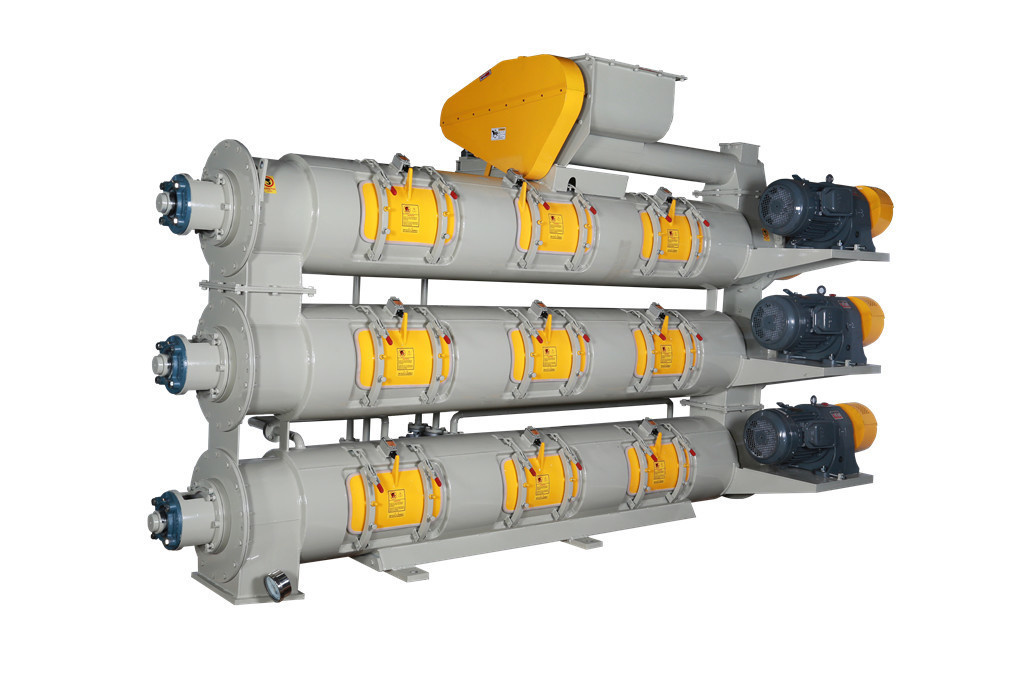

Single Shaft Conditioner (SSC)

Single Shaft Conditioner with combinations of different paddle arrangements and heat jackets can be used for many purposes such as increasing retention time, improving the incorporation of steam and ingredients, also for continuous feeding

Features and Benefits

- Main shaft bearing housing mounted on the exterior of the mixing chamber for the sanitary requirement.

- Transmission with V-belts

- Large inspection door for easy maintenance and inspection with safety switch.

- Heat jacket by steam or electrical for heating action

- Extended retention time and heating to improve feed cooking.

- Direct steam addition injection available,

- Specialized paddle arrangement for longer retention time, better mixing, or continuous feeding purposes.

- Optional: temperature sensor on the outlet

| Model | KX-3025 | KX-3030 | KX-3324 | KX-3824 | KX-3830 | KX-4725 | KX-5428 | KX-6028 |

| Main Motor (HP) | 5 | 5 | 7.5 | 7.5 | 7.5 | 15 | 20 | 20 |