Twin Shaft Extruder Technology - Co-Rotating Screw Extruder (for food, snack, texturized meat products)

With over 20 years of experience in feed and food extrusion. IDAH Co-Rotating twin-screw extruder is a reliable system for a wide range of products of TVP (Textured Vegetable Protein). Not only manufacturing the machine, but IDAH also established a food production plant by using two co-rotating extruders.

The co-rotating twin-screw extruder is used for texturized meat and other TVP-related production.

IDAH can help you experience the actual prototyping in Idah Innovation Center by utilizing IDAH equipment and technology. During this process, not only you can enhance your expertise, but we can also share the know-how and experience in the actual production of TVP. Our expert team will help you with training courses and the actual learning process, helping you become one step ahead in the market.

Features and Benefit

- The reduced specific energy input to reach higher energy efficiency

- Gentle handling for maximum product quality

- Electric heater system with accurate temperature control for quick and stable operation

- DC power supply

- Handwheel-operated barrel ejection unit for quick liner and screw cleaning

- Variable screw design, interchangeable for feeding, mixing, cooking, and pressure building purpose

- The direct motor is driven with an auto-lubricated bearing for long use life

- Inverter controlled water pump for stable water feeding

- Computerized PLC control for easy operation

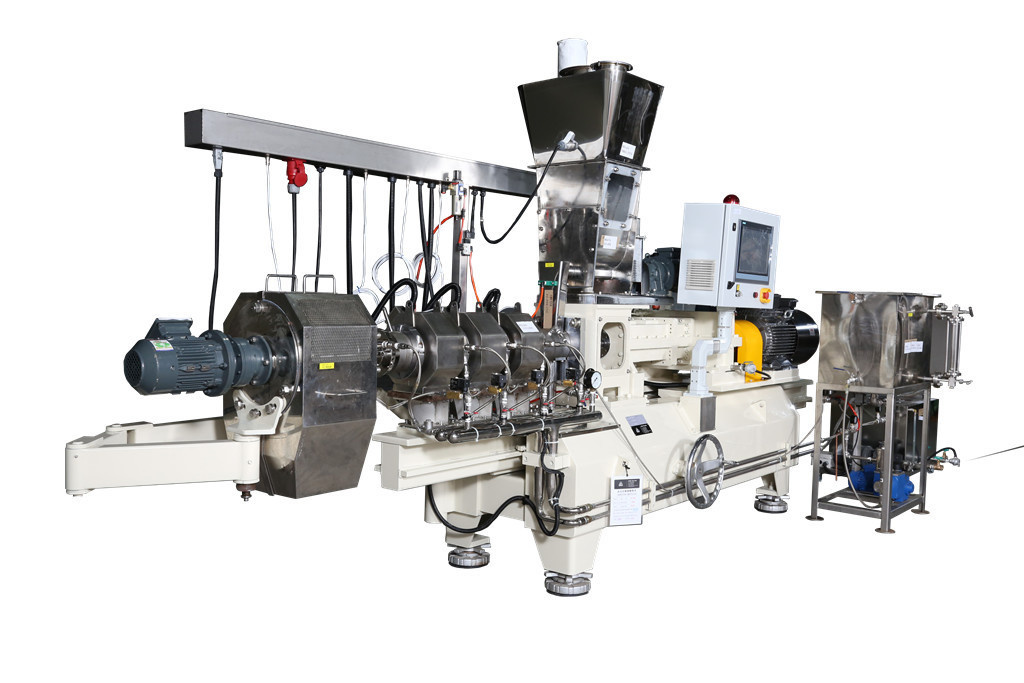

EP-50DA Twin Screw Extruder

This extruder consists of two co-rotating identical screws which rotate inside the electrically heated barrel. The barrel is placed on the railing and can easily slide out for easy cleaning. The screw configuration can be modified to accommodate different kinds of products. This extruder can be used for the production of Textured Vegetable Protein (TVP), High Moisture Meat Analogue (HMMA), and snacks.

ZPT-58D Twin Screw Extruder

The ZPT-58D is manufactured with a flexible modular design. The barrel is equipped with high-efficiency cartridge heating & water cooling. The barrel can easily be disassembled after production. This ZPT-58D is used for producing TVP, HMMA, and pet food production.

Pea Flour-Based Snack Produced in IDAH Innovation Center

One of our customers is exploring the abundant pea flour in the production of snacks. They reached out to us for consultation and hands-on experience in producing this snack with the EP-50D co-rotating twin-screw extruder. The experiment is successful and the product can already be found in the market.

Extrusion for Pet Food Production

One of our customers in Thailand wanted to look for a machine that can help to emulsify ground meat and liquid. This ZPT-58D is used for producing the meat slurry, used for pet food production.

| Model | EP-50D | ZPT-58D |

| Main Motor (HP) | 30 | 50 |

| Capacity1 (kg/h) | 25-30 | 50-60 |

Note:

1) Texturized Vegetable protein