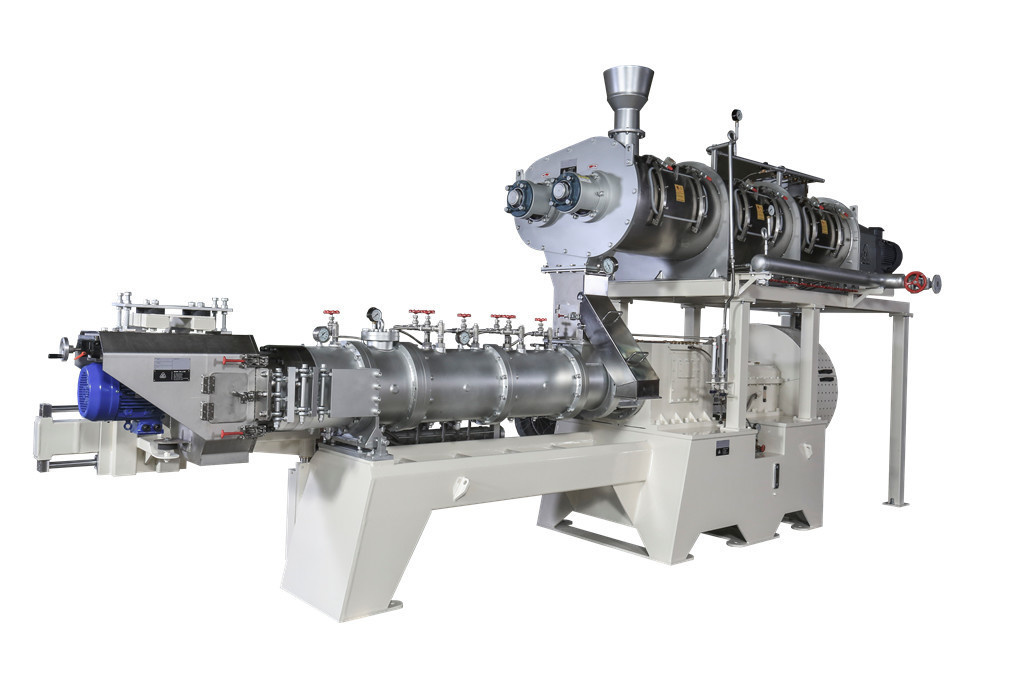

Patented Extruder Technology - Counter-rotating Twin Screw Extruder (for Aqua Feed and Pet Food)

To meet new formulation challenges, a revolutionary extrusion system designed to fit the local markets was required. With a 40-year history in feed production, lDAH developed its answer: ContraTwin.

lt is designed with twin-screw extrusion features but with re-engineered screw designs and rotation direction to accommodate future feed formulation. Developed to convey very sticky and puffy material (such as high fiber materials like plant protein), ContraTwin uses a very positive pump that does not waste mechanical energy or shear. For tougher materials operators can perform cooking in the mid-barrel system: this is where the actual work is done. The result of this strong pump and cooking significantly increases efficiency and utilizes low Specific Mechanical Energy (SME) when compared with other single or co-rotating twin-screw extrusions. The highest efficiency extrusion solution is therefore born.

For Aqua feed

Production of premium quality floating and sinking fish feed, for both fresh water and saltwater fish. The twin-screw design enables the incorporation of higher protein content in the formulation

For Pet food

This extruder is suitable for the production of cat food, dog food, and rabbit food, or any pet food which needs incorporation of high protein content in the formulation.

Features and Benefits

- Patented counter-rotating twin screws rotating system

- Controlled and full utilization of the specific mechanical energy (SME) and specific thermal energy (STE), allowing precise control of the extrusion process

- Gentle handling for maximum product quality

- V-belt pulley motor is driven with auto-lubricated bearing for long use life

- Segmented screw design can be configured to attain different production characteristics

- Multiple direct injection ports for water and steam to control extrusion temperatures

- Process management from raw material feeding, steam and water addition, main shaft speed (optional with additional inverter), and process temperature by the control system

- Computerized PLC control for easy operation (optional HMI control panel)

- Robust transmission system with gearbox and bearing house individually interconnected

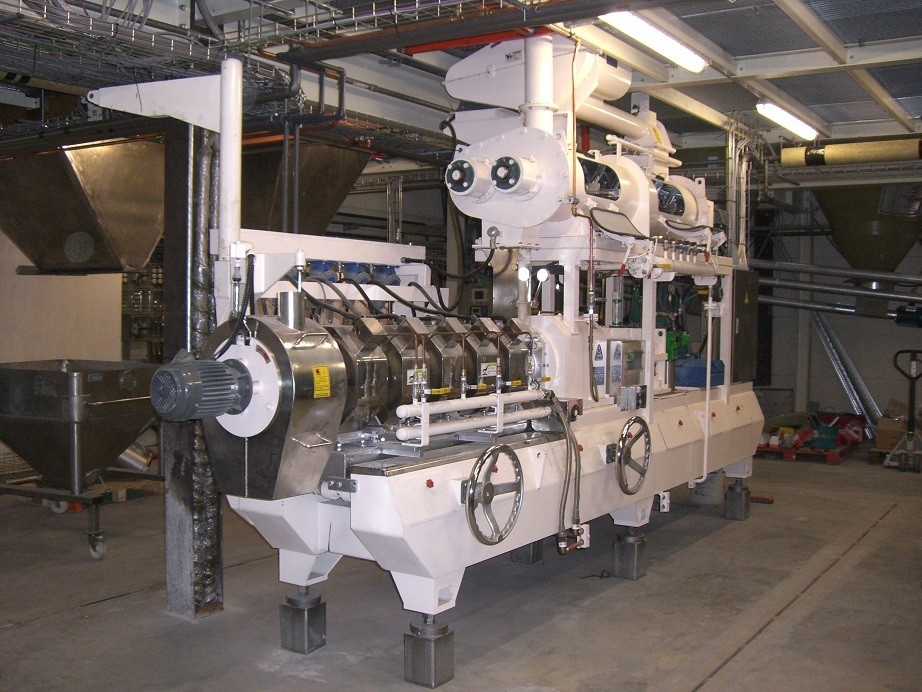

EP-76D Quick Changeover Extruder

EP-76D is a model of ContraTwin extruder which can be used for small to medium size industry. The barrel and liner can slide out and reveal the screw, thus offer high accessibility to the extruder screw. This properties will benefit the user with a high frequency of formula changes.

Features and Benefits

- Electric heater with accurate temperature control system for quick and stable operation

- DC-powered motor

- Handwheel-operated barrel ejection unit for quick cleaning

- The direct motor is driven with an auto-lubricated bearing for long use life

- Special rail-supporter and new washing table design for quick and easy clean

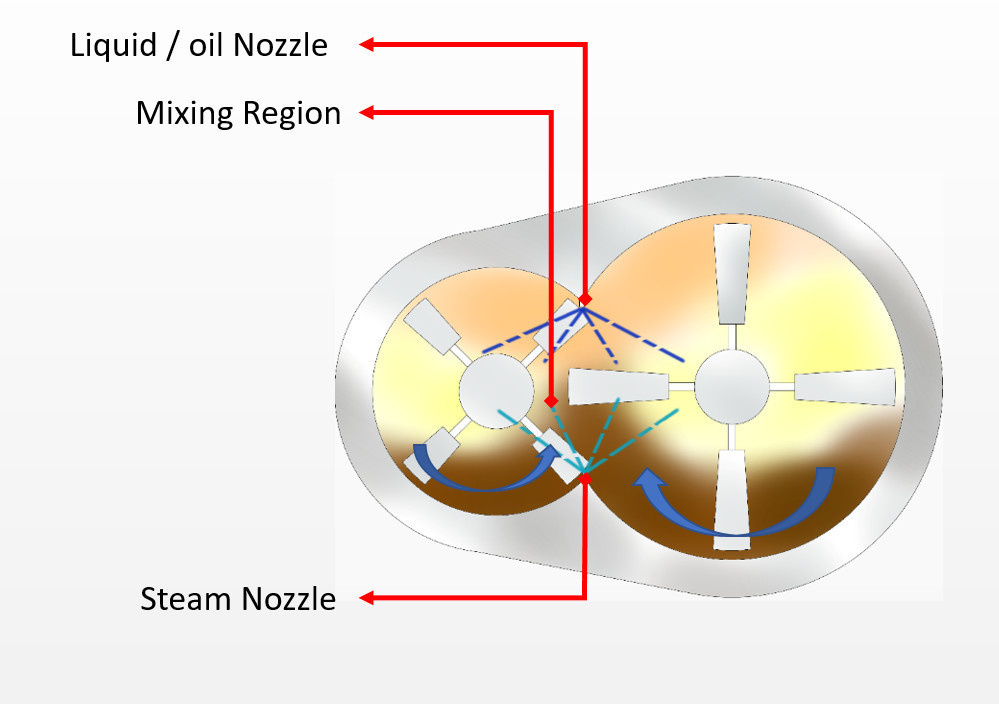

Differential Diameter Conditioner (DDC) in Extrusion System

A DDC is inseparable in the extrusion system for producing aquafeed and pet food. The DDC has two functions. The first is for cooking the raw material. Steam will be sprayed with special nozzles to mist form to increase the material mixing. The second is for liquid addition, in DDC, many forms of liquid, oil, soluble proteins, etc. can be added to the raw material.

| Model | EP-76D | EP-137D | EP-156D | EP-156DL | EP-190D |

| Main Motor (HP) | 150 | 200 | 250 | 350 | 450 |

| Capacity1 (t/h) | 0.5-1.0 | 0.8-2.5 | 1.0-5.0 | 2.0-5.0 | 3.0-6.0 |

| Capacity2 (t/h) | 1.0-2.0 | 3.5-4.0 | 5.0-7.0 | 5.0-8.0 | 8.0-12.0 |

Note:

1) Aquatic floating feed, plate die hole size Ø 1.5 - 4.0 mm

2) Aquatic floating feed, plate die hole size Ø 4.0 - 10.0 mm

| Model | EP-76D | EP137 | EP-156D | EP-156DL | EP-190D |

| Main Motor (HP) | 150 | 200 | 250 | 350 | 450 |

| Capacity1 (t/h) | 1.0-2.0 | 3.5-4.0 | 5.0-7.0 | 5.0-8.0 | 8.0-12.0 |

| Capacity2 (t/h) | 0.9-1.8 | 2.5-3.5 | 4.5-6.0 | 4.5-7.0 | 7.0-10.0 |

Note:

1) Dog food, sphere shape, plate die hole size Ø 4.0 mm

2) Cat food, sphere shape, plate die hole size Ø 3.0 mm