Clean material - Gravity Separation Feeder (for Feeding into Hammer Mill and Fine Grinder)

IDAH grinder is equipped with a gravity separator feeder which can be used for pre cleaning raw material. Heavy particles and ferrous items can be removed by the use of gravity separation technology and a permanent magnet.

Can be applied with all type of Hammer mill, Gravity Separation Feeder eliminates the heavy particles by the airflow with steadily feeding rate in animal feed, pet food, aqua feed(floating and sinking)

Features and Benefits

- Heavy particle removal lower screen breakages and hammer wear-out

- Adjustable feeding rate

- Permanent magnet separator to remove screw, nails, iron bits, and other magnetic material

- The raw material will be directed by airflow

- Adjustable air flaps to control the gravity separation

- Large inlet opening over hammer mill length for higher efficiency

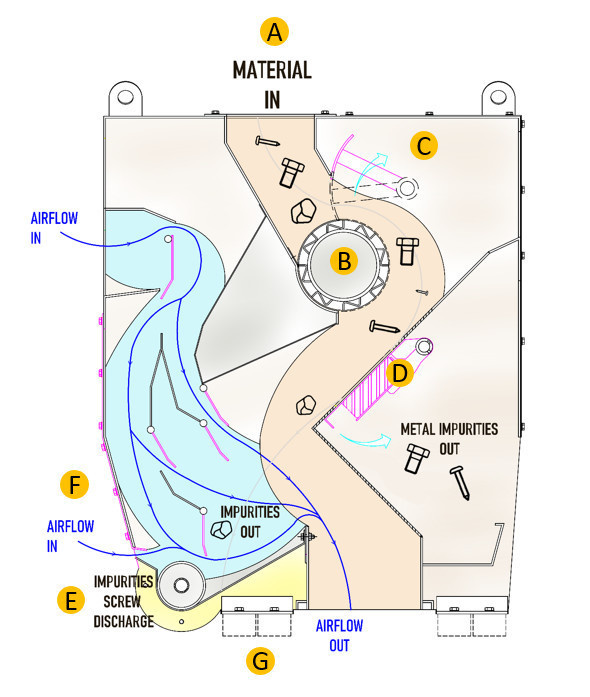

Components of Gravity Separation

The Gravity Separation feeder (PG- and XRF-series) is able to separate the material by utilizing gravity force, magnetic force, and airflow. The components are as follows:

- Material inlet.

- Rotary gear feeder

Operation speed is adjustable through the control system. - Feeder flap

The width of the opening will determine the amount of material coming in. -

Magnet block

This part will take out nails, screws, iron bits, and other magnetic metal -

Impurity screw

This screw take out all the heavier non-metal impurities -

Air inlet flap

Manually adjusted to limit the air intake to the gravity separation feeder -

G. Anti-vibration base

Absorb all vibration generated by the grinding machine.

| Model | PG-05 | PG-10 |

|

Feeder Motor (HP) |

2 | 3 |

|

Operation capacity1 (t/h) |

4-5 | 8-10 |

Note:

1) Raw material for feed, powder, and grains, moisture content <12%, oil content<6%

| Model | XRF-800 | XRF-1000 | XRF-1400 |

|

Feeder Motor (HP) |

2 | 3 | 3 |

|

Operation capacity1 (t/h) |

4-5 | 5-7 | 8-10 |

Note:

1) Raw material for feed, powder, and grains, moisture content <12%, oil content<6%