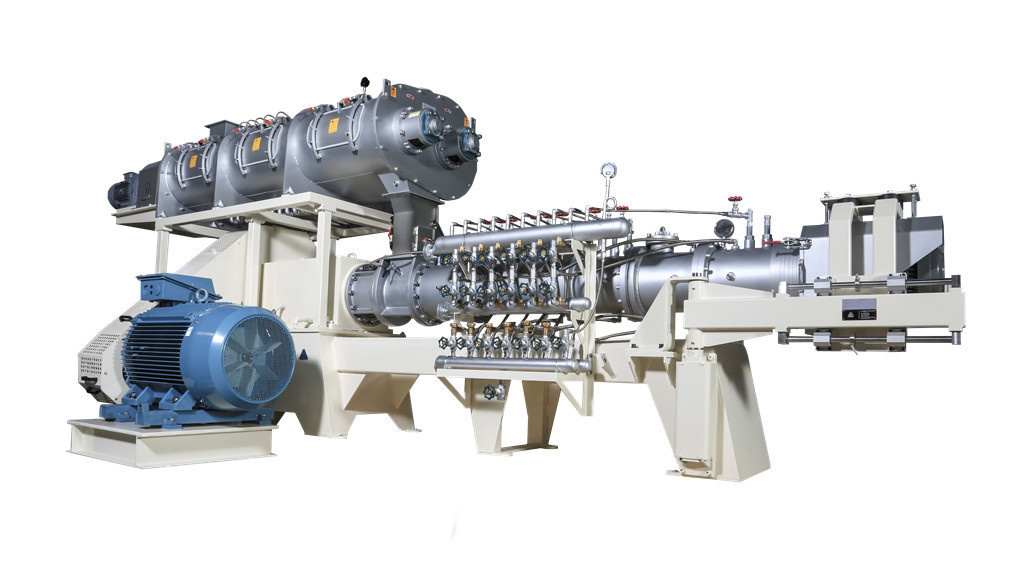

High Quality Extruder - Single Screw Extruder (for Aqua Feed and Pet Food)

Since introduced in the 1980s, IDAH EP-series single-screw extruders have been used worldwide for the production of premium quality feed and food. The unique design of the screw and barrel liner can generate a higher degree of cooking. With the incorporation of numerous innovative designs, high-quality materials, and precise manufacturing processes, IDAH extruders can perform energy-efficient extrusion cooking.

Producing high-quality extruded aqua feed with good water stability. Floating, slow sinking, and sinking extruded aqua feed for 1.0 to 30 mm extrudates. Special processing for small pellets with a nice appearance.

Producing pet food in various forms and shapes. With the precise cutting device, ensuring a smooth pellet surface.

Features and Benefits

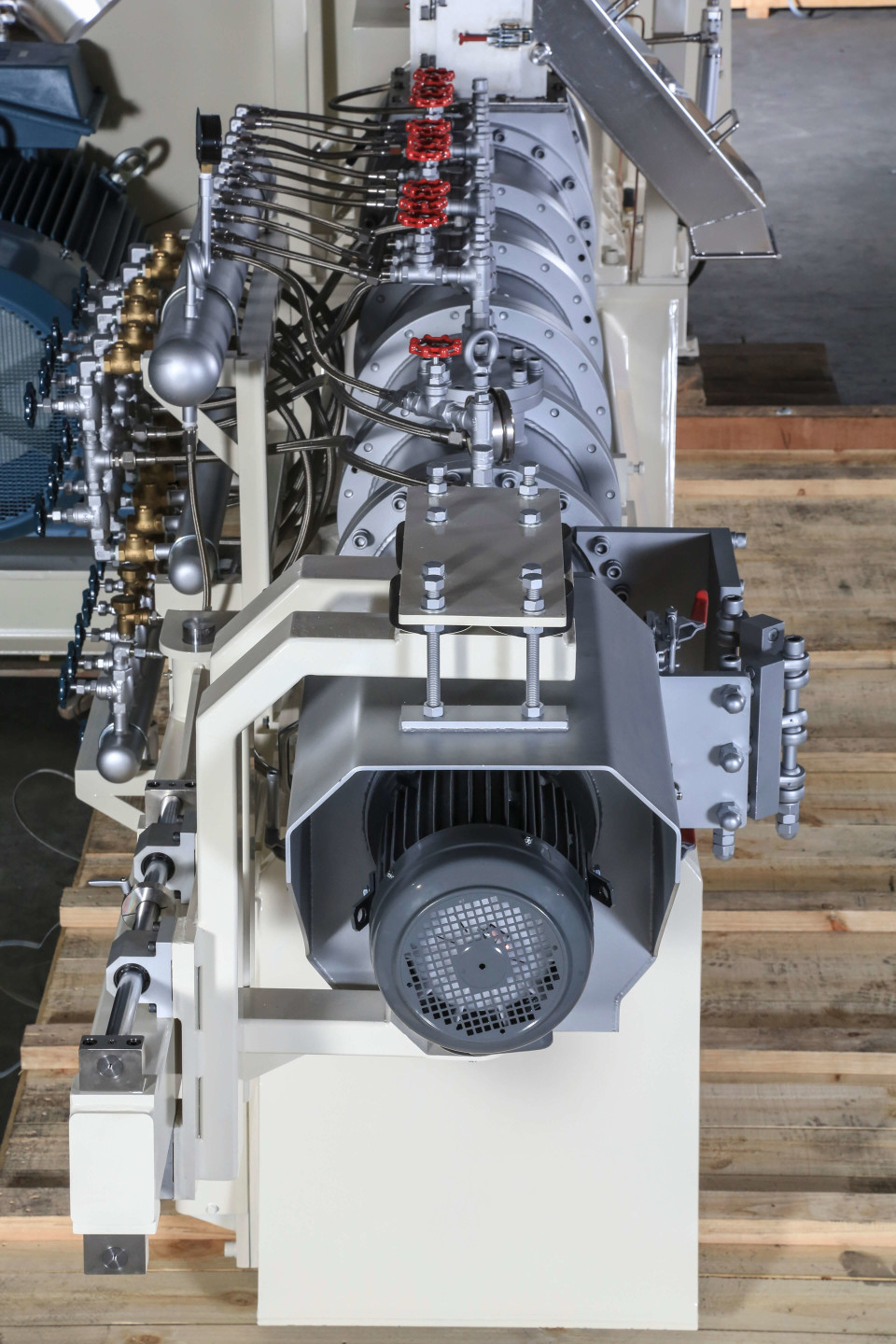

- V-belt pulley motor is driven with auto-lubricated bearing for long use life.

- Gentle handling for maximum product quality

- Segmented screw design can be configured to attain different production characteristics

- Multiple direct injection ports for water and steam to control extrusion temperatures

- High wear-resistant parts are made from special heat-treated alloy steel

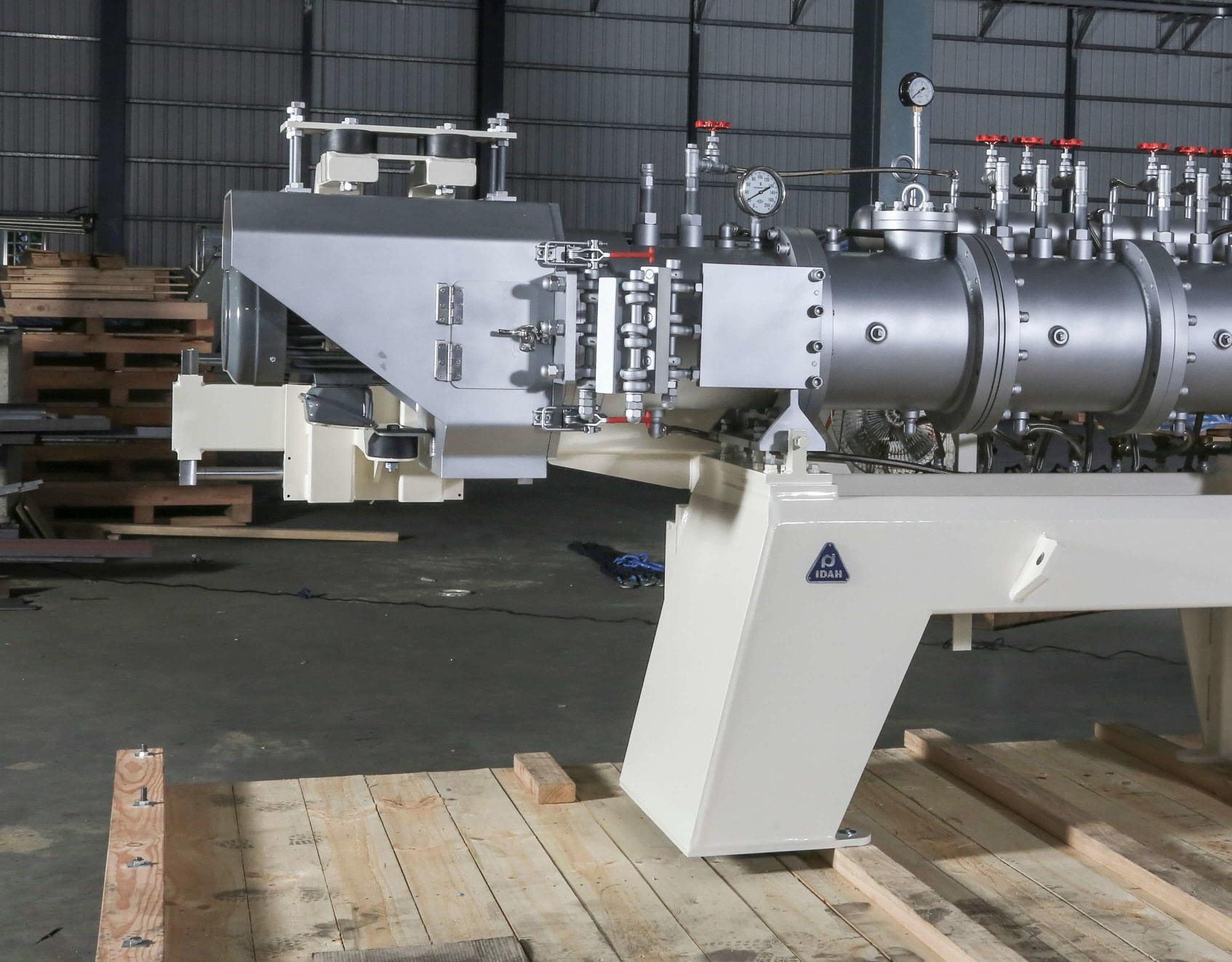

- Process management from raw material feeding, steam and water addition, barrel extrusion temperature, and the control system

- Computerized PLC control for easy operation. With optional HMI on-site control

- Controlled and full utilization of the specific mechanical energy (SME) and specific thermal energy (STE), allowing precise control of the extrusion process for uniform expansion and sufficient cooking

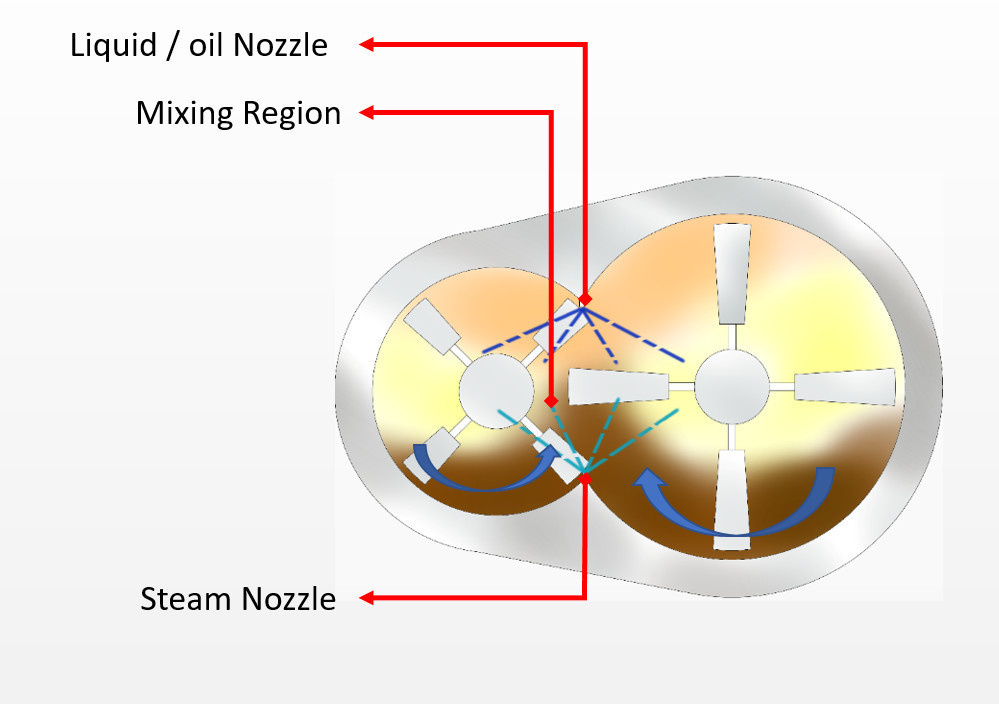

Differential Diameter Conditioner (DDC) in Extrusion System

A DDC is inseparable in the extrusion system for producing aquafeed and pet food. The DDC has two functions. The first is for cooking the raw material. Steam will be sprayed with special nozzles to mist form to increase the material mixing. The second is for liquid addition, in DDC, many forms of liquid, oil, soluble proteins, etc. can be added to the raw material.

| Model | EP-150 | EP-170D | EP-170-6 | EP-218 | EP-238 |

| Main Motor (HP) | 150 | 200 | 250 | 350 | 450 |

| Capacity1 (t/h) | 0.8-2.5 | 0.5-1.0 | 1.0-5.0 | 2.0-5.0 | 3.0-6.0 |

| Capacity2 (t/h) | 1.0-2.0 | 3.5-4.0 | 5.0-7.0 | 5.0-8.0 | 8.0-12.0 |

Note:

1) Aquatic floating feed, plate die hole size Ø 1.5 - 4.0 mm

2) Aquatic floating feed, plate die hole size Ø 4.0 - 10.0 mm

| Model | EP-150 | EP-170-6 | EP-218 | EP-238 |

| Main Motor (HP) | 150 | 250 | 350 | 450 |

| Capacity1 (t/h) | 1.0-2.0 | 5.0-7.0 | 5.0-8.0 | 8.0-12.0 |

| Capacity2 (t/h) | 0.9-1.8 | 4.5-6.0 | 4.5-7.0 | 7.0-10.0 |

Note:

1) Dog food, sphere shape, plate die hole size Ø 4.0 mm

2) Cat food, sphere shape, plate die hole size Ø 3.0 mm