High percentage liquid coating - Vacuum Coater (for Aqua feed, Animal Feed and Pet Food )

IDAH introduced vacuum coater to the market in the early 1990s. This vacuum coater is designed with a robust airtight body that can withstand the applied vacuum pressure to permit deep penetration of the liquid (oil, enzymes, etc.) to the material pores. The twin paddle mixing technology guarantees a thorough mixing of all types of extrudates and pellets with the applied liquid or powder. Up to 30% of liquid can be incorporated into the products.

The precise vacuum pressure permits deep penetration of additional liquid into the extrudates or pellet industry of

1. Pet food: For the application of palatants to dry kibble and petfood treat

2. Aqua feed: Suitable for variable kinds of fresh water and salt water fish feed

3. Animal feed: For the application of enzymes, antibiotics, and other liquids.

Features and Benefits

- With twin paddle mixing technology for high mixing efficiency with high homogeneity (C.V. 3-5%) in a short time

- Gentle mixing for free-flowing pellets ensures no pellets breakage

- Precise vacuum pressure control for full penetration of liquid

- Spraying nozzles equipped with compressed air for pipe cleaning

- Airtight design with two butterfly valve designs

- Good for application of 5-30% liquid addition

Vacuum Coating of Sinking Marine Fish Feed

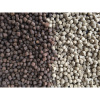

Our customer in the middle east come up to us looking for an extrusion line for producing sinking marine fish feed. We introduced them to our EP-156D extrusion system and the VC-1500 vacuum coater. The vacuum coater is able to fully coat the sinking feed. As you can see in the picture, after coating of 20% (w/w) additional oil content, the feed becomes darker in color and has a smooth surface. The customer is satisfied with the result.

| Model | VC-101 | VC-750 | VC-1500 |

| Main Motor (HP) | 0.4 | 10 | 30 |

| Operation Volume (l/batch) | 10 | 750 | 1500 |

| Min (50%) (l) | 5 | 375 | 750 |

| Max (140%) (l) | 14 | 1050 | 2100 |

Note:

1)For laboratory purposes. Contact us for more details