Uniform Drying - Carousel Dryer (for Food. Chemical, Aqua feed and Animal Feed, and Plastic Industry )

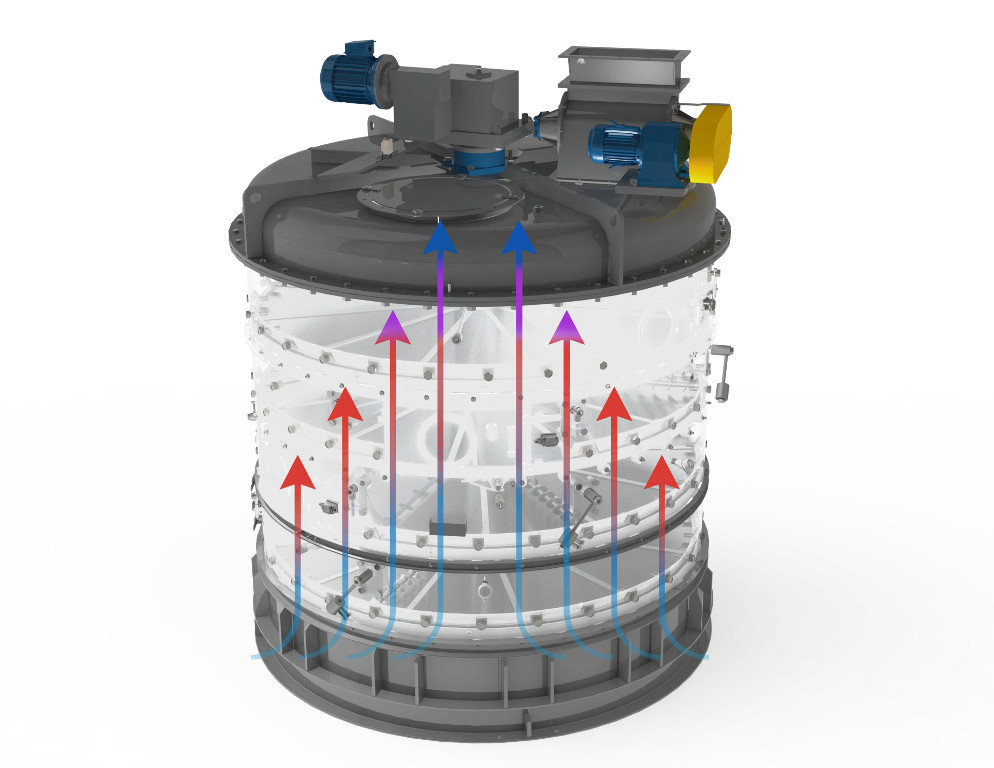

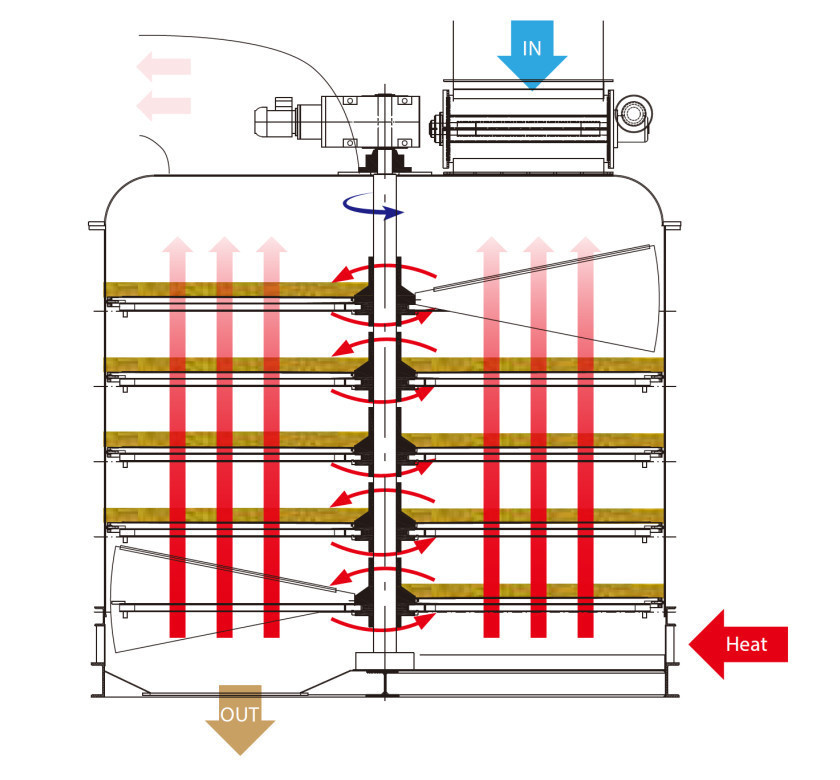

Also known as the Vertical Cross Counterflow Rotary (VCCR) dryer. The round-shaped dryer features multiple perforated screen trays forming rotating decks positioned superposing each other, the trays will carry the product to be dried. Each of the trays will be tilted by a mechanical mechanism in fixed places. When tilted, the product will slowly and gently slide down onto the subjacent deck. The stacking decks help to save energy and space requirements. All the products undergo the same drying conditions, resulting in very uniform and steady drying. Optimal counter-flow heat transfer, resulting in low energy cost. Quick changeovers in a controlled way to reduce product contamination.

Carousel dryer technology is suitable for drying any granular that requires the highest standards of sanitation.

1. Food product

2. Chemical industry

3. Pet food

4. Fish feed - fresh water and salt-water fish feed, aquarium fish feed.

5. Plastic industry

Features and Benefits

- Material rotated on multiple decks, exposed to a fixed drying air stream

- Quick product changeover only by emptying one subjacent deck

- Tilting drying tray, induce product reposition and mixing for uniform drying

- One main shaft with controllable speed using inverter

- Inlet, middle, and outlet rotary valve for continuous and controlled feeding, also act as an airlock

- Inspection windows and maintenance holes on every deck

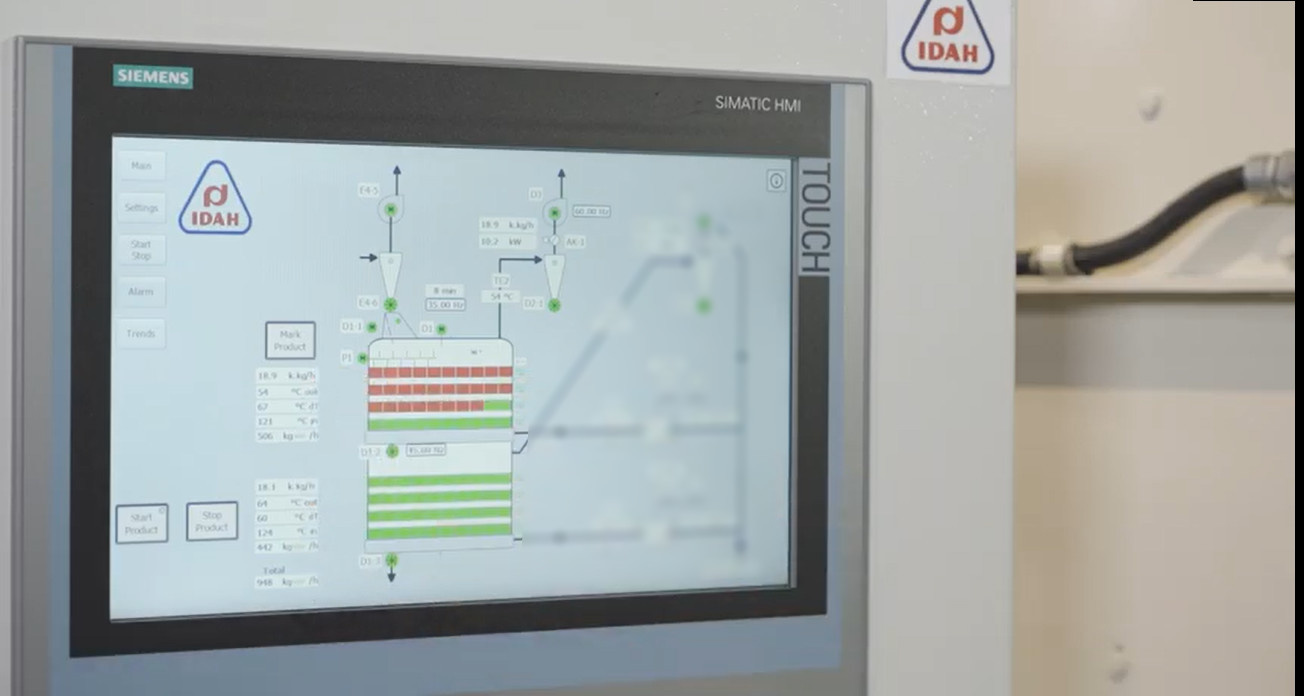

- Easy Moisture Control through HMI touch panel which includes air volume and temperature control, water evaporation calculator, and energy efficiency indication

- Optional drying air and cooling air recirculation for energy-saving and less odor control issue

Go Round for Gentle and Uniform Drying

Each pellet is carefully treated

THE PROCESS

- Round-shaped carousel dryer consists of several slowly rotating circular decks. The product to be dried is fed from the top tray

- After nearly one revolution, the product is discharged onto the next subjacent deck. During discharge, the process product is mixed, leveled again

- This process is repeated until the product is discharged from the last tray into the outlet

- Change of product without downtime, just allow one deck to be fully emptied

- The airflow is vertical and going through the perforated circular trays

- Product is moving in circles in a fixed counter-flow airflow

- The product flow is first-in, first-out(FIFO). Every pellet is getting the same treatment while passing different air volumes and temperatures

- Result is optimum drying uniformity

Detailed Design of Carousel Dryer

Designed for the production of high-quality feed

-

Adjustable retention time

Control of product layers -

Product inlet rotary valve

No product damaging even with 100% filling -

Round shape

- No dead spots

- Improve air distribution

- Better hygiene -

Product spreader

Spreading product and break up clumps -

Short drop distance

Gentle product discharge and mixing for uniform drying -

Lower layer 50-200mm

- Low compressive load of product

- Improve moisture uniformity -

Mechanical tilting cam device

Mix product with multiple tumbling

| Model | T-225-4 | T-300-5 | TT-300-4-4 |

| Capacity1 (t/h) | 1.5-2.0 | 3.0-3.5 | 5.0-6.0 |

| Capacity2 (t/h) | 1.0-1.5 | 2.0-2.5 | 4.0-5.0 |

| Capacity3 (t/h) | 3.5-4.0 | N/A | N/A |

Note:

1) Floating Fish Feed, die hole size Ø 3.0 mm, moisture in 24% (wb), moisture out 10% (wb)

2) Sinking Fish Feed, die hole size Ø 3.0 mm, moisture in 26% (wb), moisture out 10% (wb)

3) Shrimp Feed, die hole size Ø 2.0 mm, moisture in 16% (wb), moisture out 12% (wb)