High quality aqua feed pellets - Pellet Mill (for Aqua feed)

Pelleting system for aqua feed consists of a feeder, pre-conditioners, a pelleting machine, and a post-conditioner.

IDAH pellet mills are born from years of experience and continuous improvements to ensure high production efficiency at the lowest cost. IDAH has standardized the pellet die and the roller shell for aqua feed production. The compression ratio of our pellet die is specially designed to ensure compact and tough pellets with higher PDI. The roller shells are designed individually for each different hole size.

IDAH has been producing machinery for aqua feed since 1974. IDAH pellet mill is well-known because we consider the design of conditioning. The “High Moisture Pelleting” method can be achieved through our advanced pre-conditioning technology. Careful control in the incorporation of heat, moisture, and time provides sufficient cooking for the production of premium quality feeds with good water stability to the market. In addition to altering the product quality, sufficient pre-conditioning also reduces wear out of the parts.

The “High Moisture Pelleting” method can be applied for the production of premium quality sinking feeds, including fish feed (for milkfish, tilapia, catfish, etc,) and shrimp feed.

Features and Benefits

- Homogeneous conditioning to effectively improve starch cooking, increase capacity, and lower production cost

- Steady feeding to ensure uniformity of material conditioning process and product quality

- Quick-release design reduces down-time for replacing dies and rollers

- Two rollers with eccentric roller shaft design.

- Robust design with integrated base

- Rubber base for absorbing vibration (Longevity and low maintenance cost)

- Rotation speed control with V-belt drive train from the motor to the driven wheel

- Die speed varies from 4.5 to 8.5 m/s depend on the pellet formula

- Sturdy cutting knife, fixed to the door, with optional fixed to the machine body

- Shear pin design protects pellet mill from damage

- An Optional continuous greasing system ensures bearings running smoothly.

- Made from high-quality steel material.

- Computerized control with optional HMI local panel

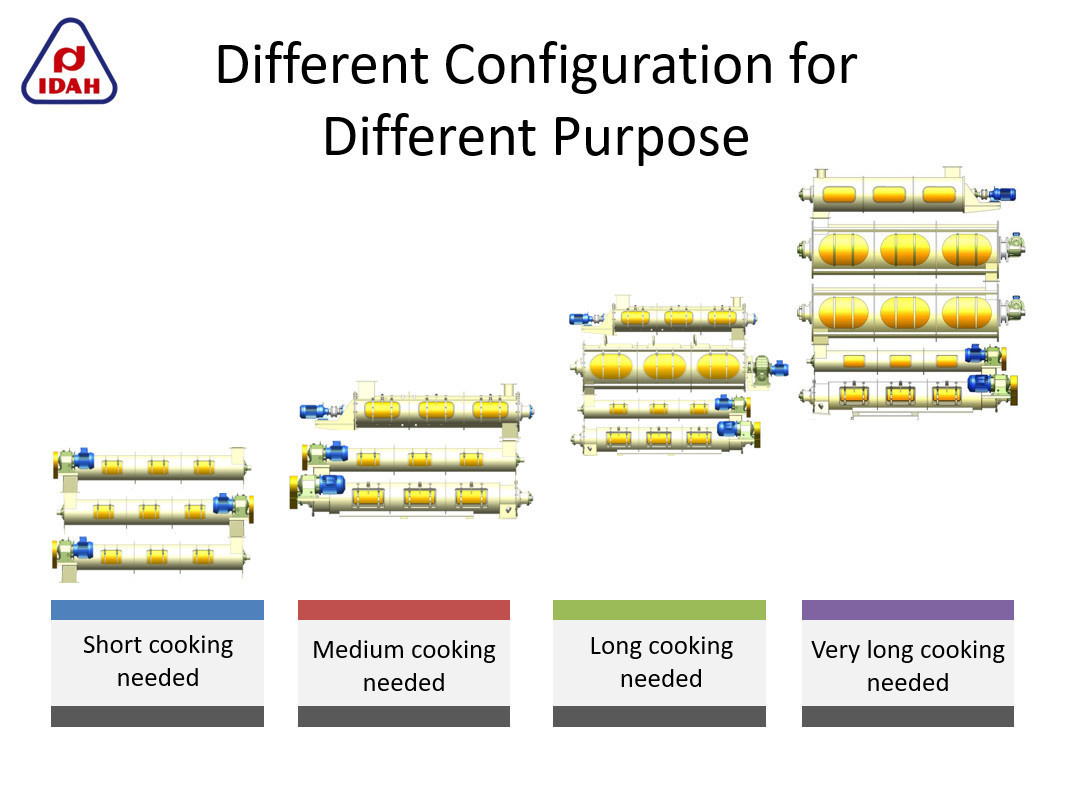

Different Pre-Conditioner for Aqua Feed pelleting

In general, the precondition for aqua feed consists of:

-

Differential Diameter Conditioner (DDC)

This is used for pre-cooking of the material, steam enters through the nozzles and is mixed with the raw material. -

Long Term Conditioner (LTC)

This is used for retention time during cooking, usually placed below the DDC, to prolong the material cooking time. - Single Shaft Conditioner (SSC)

There are two kinds of SSC, with and without heat jackets. The SSC is used for heating the material (by heat jacket or direct steam injection), breaking lumps that are formed in the LTC, and continuous feeding to the pellet mill.

| Model | PM-42SA | PM-51SA | PM-53SA | PM-53F | PM-635D |

| Main Motor (HP) | 100 | 150 | 200 | 215 | 300 |

| Operation Capacity1 (t/h) | 1.3-1.5 | 2.3-2.5 | 3.0-3.5 | 3.5-4.0 | 4.5-5.0 |

| Operation Capacity2 (t/h) | 3.0-4.0 | 4.0-5.0 | 5.0-6.0 | 6.0-8.0 | 9.0-10.0 |

Note:

1) Shrimp Feed, pellet die hole size Ø 2.0 mm

2) Sinking Fish Feed, pellet die hole size Ø 3.0 mm