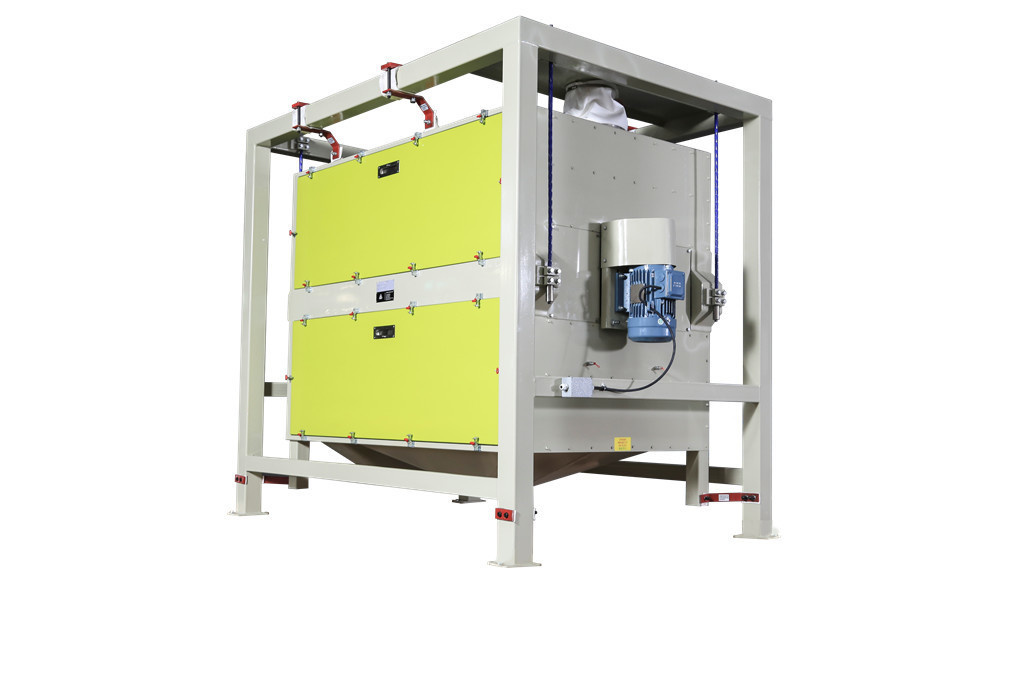

Dust Separator and Classification - Plansifter (for food, aqua feed, and animal feed Industry)

Aqua feed and pet food production lines incorporate many sifters in their process, whether in grinding, crumbling, or packing systems. For example, the requirement of the material fineness after grinding may reach up to 80 to 100 mesh (177 to 149 microns). So not only do we need to have a sifter with good sieving efficiency, but also have a proven capability to be used in every system.

The RS-series plansifter can separate coarse and light material (such as husk) in the grinding system. In a crumbling system, it can separate the pellet crumbles specifically based on each target size ex: in the range of 300 to 700 microns. Also before packaging, this plansifter can be used as dust-remover to ensure the customer will receive dust-free pellets.

Plansifter is widely used in product screening of ground raw material and grading of crumbled pellet in aqua feed and animal feed.

Features and Benefits

- The design of the door lock ensures tight fixing, lowers the dust “leaking” during sifting

- Screen design with three benefits: Drawer design, a long-lasting aluminum outer mainframe with replaceable screen frame for faster, easier, and cheaper screen maintenance

- High surface area screen for higher sifting efficiency. The smaller amount of screen deck needed compared to conventional plansifter

- Centrifugal force is generated by utilizing a drive shaft with a keyed counterweight that runs on roller bearings, the electric motor directly mounted to the sifter’s support frame

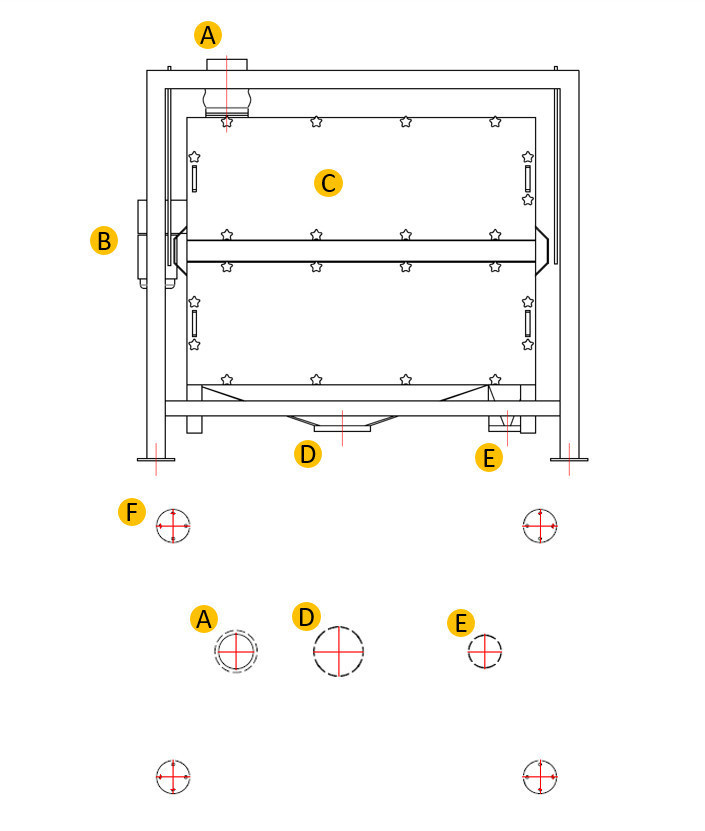

RS-Series Plansifter for Grinding System

Plansifter can be used for separating big-size material after grinding. The big material will be separated from the grinding material and go back to the grinding chamber.

-

Material inlet.

A canvas cloth will be used to connect the inlet and the piping -

Motor

Unique motor drive to generate oscillation of the sifting chamber -

Sifting Chamber

Multiple layers of screen are placed in a stacked position to separate big materials -

Product Outlet

The material that passed the screen will go out from this hole -

Big Material Outlet

Bigger size material will go out from this hole - Machine Footing

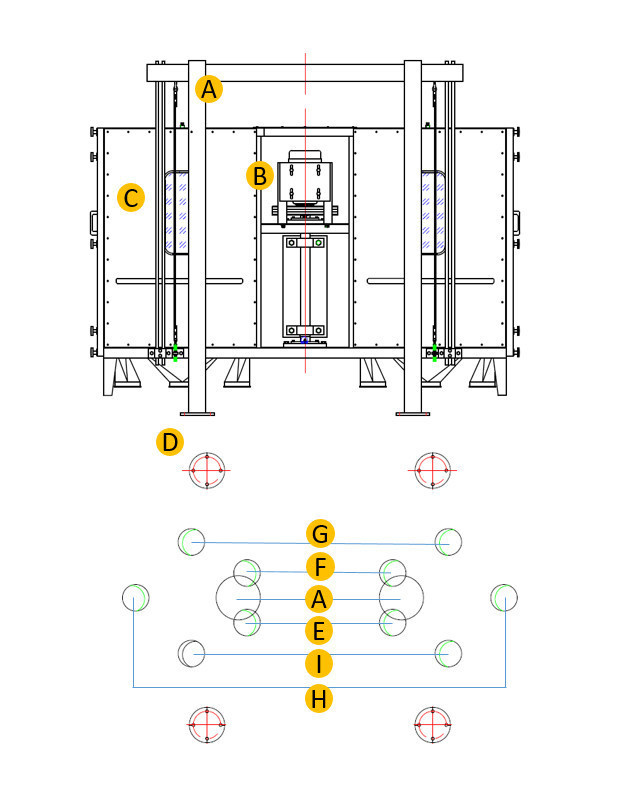

RS-Series Plansifter for Crumbled Material

In animal feed and shrimp feed production, crumbling is a common practice. Depending on the requirement, the crumbled product can be fed as a compound or separated based on its size. Plansifter can help to separate the crumbled materials into several different sizes.

-

Material inlet.

A canvas cloth will be used to connect the inlet and the piping -

Motor

Unique motor drive to generate oscillation of the sifting chamber -

Sifting Chamber

Multiple layers of screen are placed in a stacked position to separate big materials - Machine Footing

- Product no 0 outlet

- Product no 1 outlet

- Product no 2 outlet

- Big particle

Bigger size material will go out from this hole - Small particle

During the crumbling process, some dust will be generated and go out from this hole

| Model | RS-830-1 | RS-830-2 | RS-830AD-12 | RS110170 | RS-120K |

| Model | Single chamber | Double chamber | Double chamber | Drawer type | Drawer type |

| Outlet | Single | Single | Multiple1 | Single | Single |

| Capacity2 (t/h) | 1.0-2.0 | 4.0-5.0 | 4.0-5.0 | 9.0-10.0 | 15.0-16.0 |

Note:

1) For grading of crumbled material

2) Using 30 mesh screen size