Screw Conveying - Screw Conveyor and Feeder (for Food, Aqua feed, Animal Feed and Pet Food )

The screw conveyor is the key device for precisely feeding material to the dosing system.

The screw conveyor design ensures self-cleaning, less maintenance, eminent productivity, and comes in modular design.

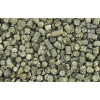

For material transport in raw material and end-product of food, pet food, animal feed, aqua feed (floating and sinking), and other powder or granule form materials.

Features and Benefits

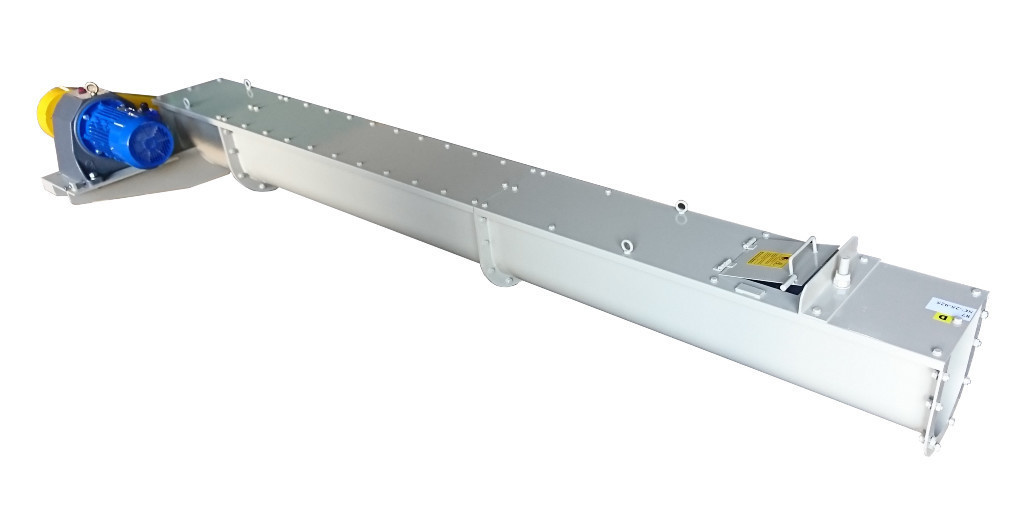

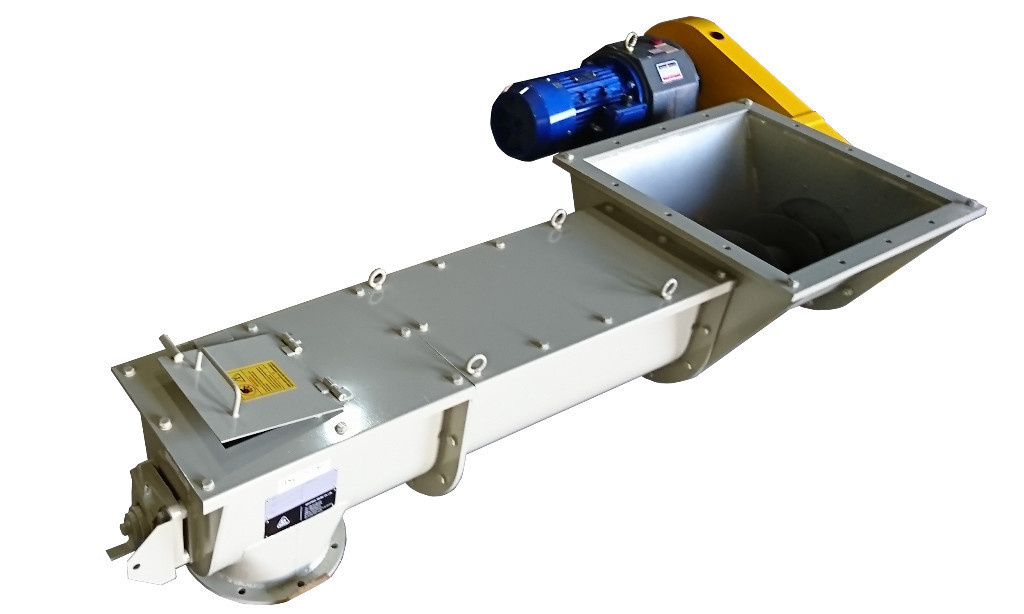

- Two types of screw conveyors to fit different process needs: trough (U shape) screw conveyor and tubular screw conveyor

- End bearing assembly with shaft seal for material and bearing partition

- Sturdy material for long use life and low maintenance

- Removable cover and inspection window for ease of cleaning

- Equipped with a zero-motion sensor, and an anti-block sensor for safe operation

- Sanitary design with enclosed housing to ensure a clean working environment

- The middle bearing will hold the main shaft on-position

- Customizable polygonal or cylindrical inlet and outlet

- The customized pitch of the screw flight design

- Optional inverter to control speed for energy cost saving

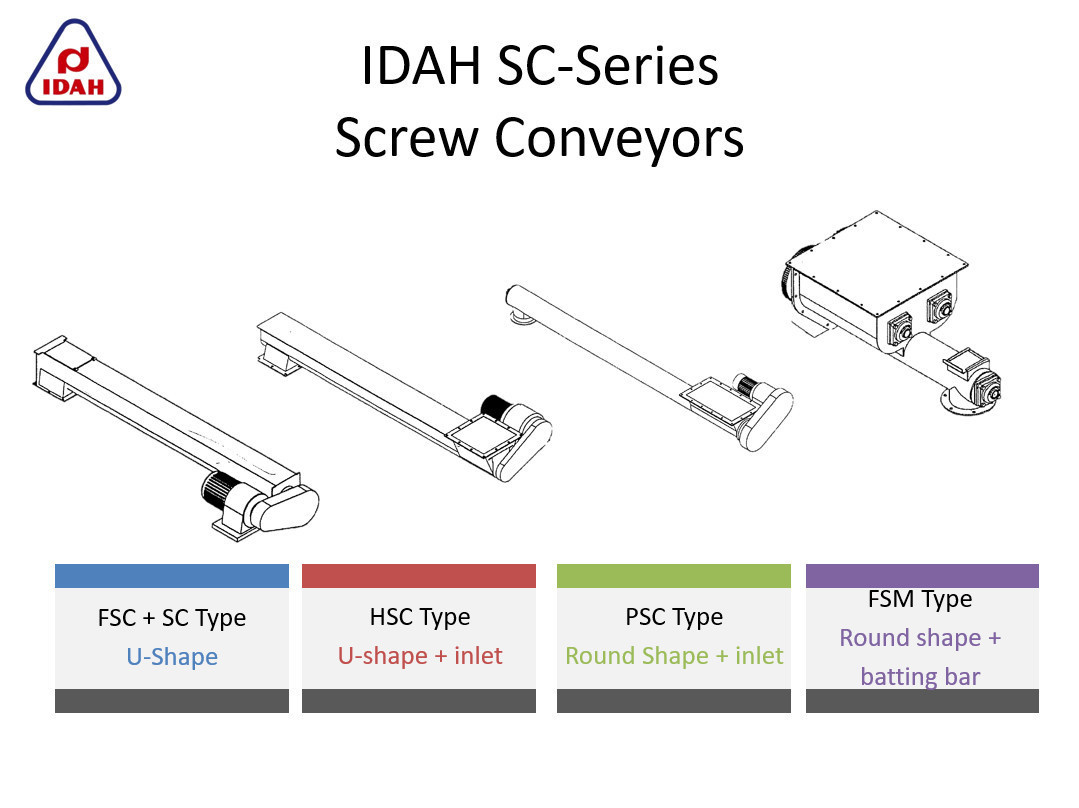

IDAH SC-Series Screw

There are 4 series of screw conveyors available in IDAH:

- FSC- and SC-series are the basic trough (U-shape) screw conveyors. FSC is used for feeding purposes, while SC is used for material transportation purposes.

- HSC-series is also a trough (U-shape) screw conveyor, but it has a defined inlet hole, which is pre-shaped for specific inlet hole sizes.

- PSC-series is a cylinder shape screw conveyor. The main usage of this screw conveyor is for precise feeding.

- FSM-series is a cylinder shape screw conveyor. The inlet is equipped with a stirring (batting) bar to help loosen the powdery material. This FSM series is also mainly used as a feeder.

| Model | SC-16 | SC-20 | SC-25 | SC-30 |

| Main Motor (HP) | 1 | 3 | 3 | 5 |

|

Operation Capacity1 (t/h) |

2-4 | 5-10 | 10-12 | 17-20 |

Note:

1) Raw material, density 0.5 kg/m3